Silverstream Technologies Established, in London, UK.

2010

It's simple, it's clever and it works.

A step-by-step guide on installing our system.

Aftercare services designed for agility and uptime.

A greener, brighter future for shipping.

Always learning, never standing still.

It's simple, it's clever and it works.

A step-by-step guide on installing our system.

Aftercare services designed for agility and uptime.

A greener, brighter future for shipping.

Always learning, never standing still.

Since 2010, Silverstream has successfully developed, deployed and scaled air lubrication technology across the maritime sector, making the Silverstream® System a primary choice for the shipping industry. We understand the importance and challenges that come with decarbonisation of the maritime industry. Building on our track record as an enabler in this transformation, we look forward to helping our customers through this change. Follow below to learn more about our incredible journey.

Our purpose is to transform maritime energy efficiency.

Our goal is to make air lubrication a global standard for all newbuild vessels, and to upgrade existing vessels with our proven retrofit solutions.

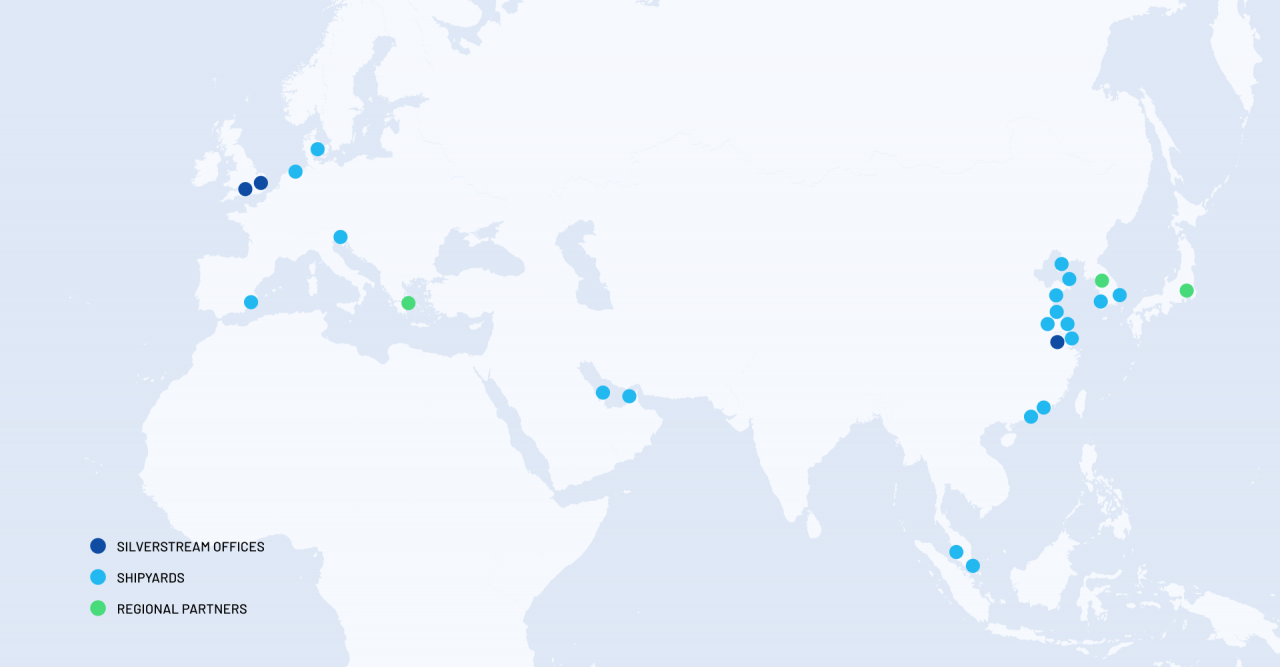

To achieve this, we work with a global network of owners, charterers, shipyards, class societies and industry associations.

Dario Bocchetti Head of Energy Saving, R&D and Ship Design, Grimaldi Group

"Our partnership with Silverstream Technologies began in 2018 with the installation of the Silverstream® System on one of our state-of-the-art GG5G class vessels. Since then, 16 vessels have been equipped, with 10 more in progress and new projects under feasibility and preliminary energy saving assessment. This collaboration reflects our shared commitment to reducing the environmental impact of shipping, and we’ve witnessed firsthand the tangible improvements in fuel efficiency and emissions reduction – for example, achieving 5-6% net savings for our GG5G RoRo fleet. Silverstream’s innovative technology is a piece more of the puzzle in helping us meet our sustainability goals, ensuring that we continue to lead the way in cleaner, more efficient maritime operations."

January 2025

William R. Burke Chief Maritime Officer, Vice Admiral (Ret.), Carnival Corporation

“Silverstream’s ability to deliver proven, verified GHG and fuel cost savings sets them apart in a crowded marketplace. Our continued partnership has thrived thanks to our shared commitment to advancing sustainability in the maritime sector. As we work towards net zero by 2050, we look forward to many more years of collaboration, driving energy efficiency, reducing fuel consumption and cutting emissions throughout our fleet.”

For more information see this press release

January 2025

Steve Brown Innovation Manager, Shell Trading

“Air lubrication technology for us has been the biggest efficiency gain.We’ve just deployed Silverstream’s technology on an LNG carrier and that’s delivering some pretty good returns already up to around 8%.”

July 2021

Shell TechXplorer Digest

Vessel Air Lubrication Helps To Reduce Maritime Emissions

“Shell originally tested the Silverstream® System on one of its chartered product tankers; the sea trials demonstrated about a 5% net efficiency gain. In 2020, Shell installed the Silverstream System on the Methane Patricia Camila liquefied natural gas (LNG) carrier, which was the first time Silverstream had installed a system on this ship type. Early testing of the system has shown power savings of up to 8%.”

2021

Alberto Portolano Project Manager AirLub Design and Integration, Grimaldi Group

“The successful trial of the Silverstream System and the CO2 reduction that it generates is an important step in Grimaldi Group’s aim to lead on shipping sustainability. The trials conducted with the ship in fully loaded service showed the air bubbles covering the entire hull bottom. We are looking forward to continuing to work closely with Silverstream to benefit from their technology on more of our market-leading ro-ro vessels.”

March 2021

Mikael Lindholm Head of Newbuilding Department, Finnlines

“Finnlines has chosen Silverstream Technologies based on their extensive experience, since they have invested significantly in research and development. We look forward to collaborating with them in future.”

May 2021

Silverstream has strong partnerships with a range of industry leaders across the global shipping industry.

We work with almost 30 shipyards and agents worldwide. The Silverstream® System has been independently verified by Lloyd’s Register, HSVA, the University of Southampton, Carnival, Shell and others.

Mr Alvin Gan Executive Vice President, Repairs & Upgrades, Seatrium Limited

“Seatrium is committed to working with our customers and partners to provide turnkey, one-stop solutions in energy efficiency retrofits for LNG carriers. Our collaboration with Silverstream Technologies is successfully delivering another retrofit of their air lubrication technology and further solidifies our position in the industry.”

April 2024

Hudong Zhonghua Shipbuilding Co., Ltd.

“We would like to express our heartfelt thanks to your company for your support during supply chain delivery and on-site installation and commissioning!”

Jan 2024

Costis J. Frangoulis Founder & CEO, Franman

“At Franman, we always strive to offer solutions that combine performance with sustainability. The integration of Silverstream’s leading air lubrication system into our portfolio will allow shipowners to not only comply with but exceed the industry's evolving regulatory and environmental standards.”

Nov 2023

Stephan Schmees Executive Board Member, Project Management Ships & Quality, Meyer Werft

“As one of the largest builders of luxury passenger vessels, we are excited to once again work with Silverstream and Carnival Corporation to deliver an efficient and environmentally superior vessel design. Carnival took the decision to add ALS to S717 quite late in the build process, so the fact we have been able to accommodate this change at short notice reflects our strong, dynamic relationship and the flexibility of the Silverstream team. We strive for high quality, expert engineering, and proven clean technologies, such as the Silverstream® System, help us achieve this.”

Sep 2021

Nick Brown Chief Operating Officer, Marine, Lloyd’s Register

“Ship owners and operators need to trust the savings and return on investment calculations that manufacturers claim. This trust can only be built by ensuring rigour and transparency within the trial process, to ensure the highest level of accuracy in the projected figures that are communicated to the market. The sea trials for the Silverstream® System have been conducted in such a way, with independence ensured throughout.”

Feb 2015

On our way to becoming a clean technology leader we have garnered an impressive list of awards and accolades.

Vessels under contract

Vessels in service

Repeat Customers

Average uptime

Since its launch in 2010, Silverstream has developed the air lubrication concept to become a successfully commercialised technology.

With founder Noah Silberschmidt at the helm, Silverstream has become a market-leading clean technology business, and the fourth fastest growing European business in 2023 as recognised by the Financial Times.

Silverstream Technologies Established, in London, UK.

2010

Full scale Air Release Unit (ARU) tested successfully at HSVA.

2011

First ARU patent application filed.

2012

First agreement signed for full scale installation with Shell.

2013

First pilot installation on MT 'Amalienborg 40K dwt tanker completed.

2014

Contract signed with Meyer Werft shipyard for first commercial installation for Norwegian Cruise Line.

2015

First commercial order from Norwegian Cruise Line on 'Norwegian Joy'.

2016

First retrofit system delivered for Carnival Cruise Line on Diamond Princess.

2017

First multi-vessel contract signed for 12 new Grimaldi Ro-Ros at Jingling shipyard (China).

2018

First LNGC retrofit installation delivered.

2019

Silverstream expands Leadership team, driving business growth.

2020

First Korean order for 12 LNGC newbuilds at Hyundai Heavy Industries shipyard.

2021

Shanghai office opened. Largest order of 84 MSC newbuild containerships.

2022

Recognised as top 25 fastest growing businesses across Europe and 3rd fastest in the UK by Financial Times.

2023

For Second year in a row, recognised as top 25 fastest growing businesses across Europe and 3rd fastest in the UK by Financial Times.

2024

Silverstream signs an MOU with HD Hyundai Marine Solution Co Ltd.

2024

The performance and impressive results from the Silverstream® system are a true reflection and testimony to our technology. The true value of this solution is our network of customers and partners who have trusted in this solution not just once but repeatedly over time. Please contact our team here to learn more about how we use data and work with our customers to ensure ultimate satisfaction and performance guarantee

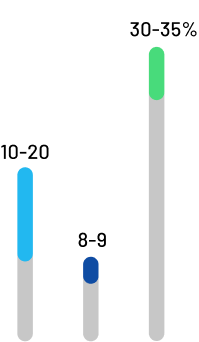

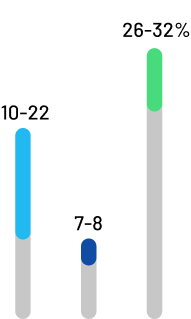

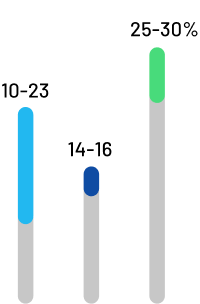

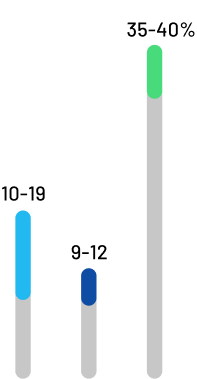

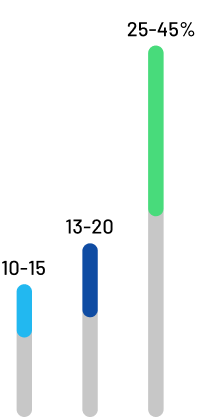

Net fuel savings

Net fuel savings

Net fuel savings

Net fuel savings

Net fuel savings

System operational speed (KTS)

Typical operational draught (M)

Flat of bottom as a % of total WSA

Worth of fuel

Tonnes of CO2

Carbon tax