- Technology Solution

- Get in Touch

-

What is Air Lubrication?

It's simple, it's clever and it works.

Installation ProcessA step-by-step guide on installing our system.

SustainabilityA greener, brighter future for shipping.

Policy & ResearchAlways learning, never standing still.

What is Air Lubrication?

It's simple, it's clever and it works.

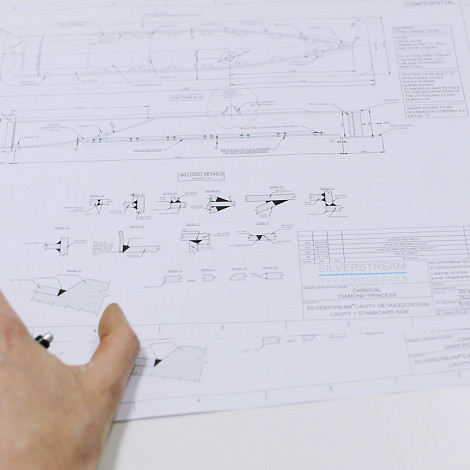

Installation Process

A step-by-step guide on installing our system.

Sustainability

A greener, brighter future for shipping.

Policy & Research

Always learning, never standing still.